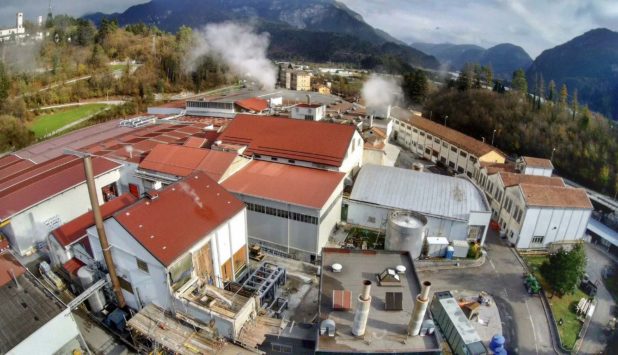

SAEL supply the 2nd water cooled sectional drive in Europe to Ermolli Paper Mill

One more time SAEL is the first. After equipping the inverters with film capacitors and ONE card, It is time to move further and set the bar higher by the water cooling system now. Once again it is time for SAEL, the benchmark! The Platform One Drive by SAEL is the unique system which combines cost-savings and best performance ever. After the rebuilding of PM1 and PM2 drives, Ermolli Paper Mill assigned to Sael the rebuilding of PM3, installing the second water-cooled sectional drive system in Europe.

SAEL and innovation: platform one drive liquid cooled, the technological gap

SAEL liquid cooled drives, practically without tangential fans (one each inverter), allowed Sael to remove all the ventilation normally mounted on every door of the electrical cabinet. The new electrical cabinets where the panels are installed, previously obligatorily and abundantly conditioned, today become normal rooms, since the system becomes independently cooled. The double-sided electrical panels, where the inverters are mounted, have closed air recirculation ensuring no contamination of dust, humidity and air acidity; they preserve over time, in a perfect manner, all electronic, electromechanical and various components.

The experience gained on the subject by the 1st water-cooled sectional drive system installed in PM3 Papermill SACI group and the excellent performance monitored over the years due above all to energy saving, will allow the paper mill to save a lot of money per year, eliminating the need for maintenance of the air conditioners and fans. For this reason and for the significant reduction of the dimensions that the system has obtained, driven by the continuous research of innovation of ERMOLLI in the search for products and systems with high technology and energy saving, SAEL has taken the order for the second WATER-COOLED plant in the paper mill sector.

The sectional drive was ready to install in March 2020, respecting the tight deadlines of the stop, is now delayed because of the situation of COVID-19. The Paper mill has decided to make the start up in July 2020. The drive system is dealt with the management of 44 AC motors of about 2,5MW of installed power; the realization, unique in its kind and coordinated with our DCS in Drive, was strongly desired to equip the paper mill with all the qualities that our PLATFORM ONE offers today in the market.