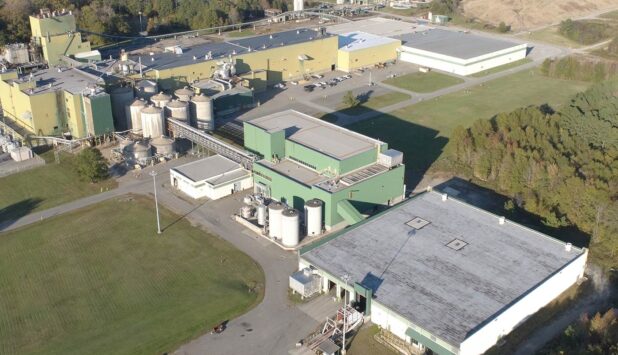

Cascades is currently proceeding with the conversion of the Bear Island site in Ashland, Virginia

The new machine will produce high-quality, lightweight, 100% recycled linerboard and medium (fluting paper) for the North American market.

The new line of Cascades XP linerboard manufactured in Bear Island will provide a full range of lighter weight grades (16 lb to 36 lb) to complement Cascades’ current line of regular and heavyweight grades. Made from 100% recycled fiber, these new containerboard grades will provide the same consistency and reliability for high-speed quality converting.

“This project is in line with the goals of our strategic plan which include, among other things, investing in our core sectors of packaging and tissue through modernization, and expanding our geographical footprint. In addition to the paper machine that is particularly well suited for conversion, the Bear Island site is strategically located for raw material sourcing and logistics.” Mario Plourde, President and Chief Executive Officer.

“The Bear Island site has several advantages including access to an experienced workforce with expertise in paper making. Moreover, the site provides a platform for continued growth through downstream converting capacity. It will also allow us to better serve our customers and expand our market share by increasing our capacity.” Charles Malo, President and Chief Operating Officer.